Ultrasonic straight screen

Scope of application:

food industry, chemical industry, metal and smelting industry, public hazard treatment

Materials:

3D printing industry raw materials, industrial commodities, cosmetics, paint, traditional Chinese medicine powder, sugar, rice flour, soybean milk, egg powder, soy sauce, fruit juice, aluminum powder, lead powder, ore, copper powder, alloy powder, electrode powder, manganese dioxide, electrolytic copper powder, point magnetic materials, grinding powder, lime, alumina, heavy calcium carbonate, quartz sand, oil consumption, wastewater, dye wastewater Additives, activated carbon

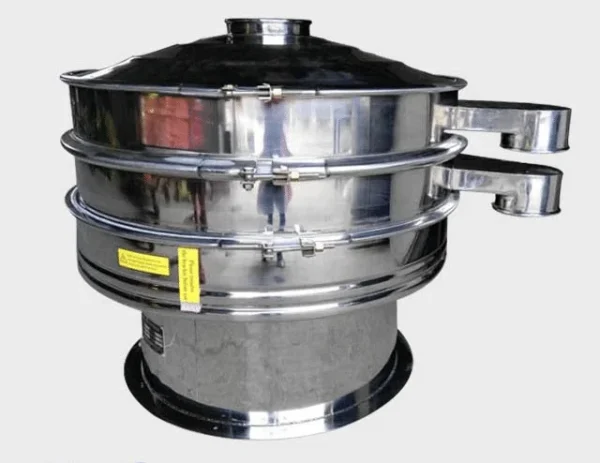

Ultrasonic straight row vibrating screen is also called ultrasonic straight row vibrating

screen. It is divided into single vibration source and double vibration source. It is

improved on the basis of the function of circular vibrating screen. It uses two vibration

motors as the vibration source. The materials enter the feeding port from the middle

and discharge directly from the discharge port in the middle of the bottom through

screening. It is suitable for installation conditions or mass continuous operation. Meet

the best screening effect of materials with different specific gravity. It is mainly used

for impurity removal and screening of powder in the process flow of powder

production line. The superposition of ultrasonic vibration can not only prevent the

mesh from blocking, but also improve the screening yield.

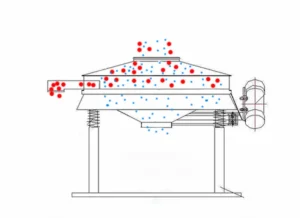

working principle:

The ultrasonic direct row screen takes a single horizontal vibrating motor as the

excitation source, and the vibrating motor is placed on one side of the machine body.

After the materials enter the equipment, they will make an elliptical motion track on

the screen surface under the force of the vibration source. At the same time, the

vibration force can produce continuous impact on the materials

The function of stripping, dispersing and reorganization enables the materials to pass

through the screen quickly. The materials that cannot pass through the screen are

discharged from the discharge port on the screen according to the movement track of

the equipment to complete the screening operation process

Product features:

- Simple structure, convenient operation, large processing capacity, high production efficiency and convenient disassembly and maintenance;

- Low energy consumption, low noise and high screening efficiency;

- Not limited by the installation conditions of the occupied space;

- Automatic work, which can work continuously for 24 hours;

- Tight sealing, no leakage of liquid and no flying of powder;

- Easy to clean, no sanitary dead corner, compound GMP specification

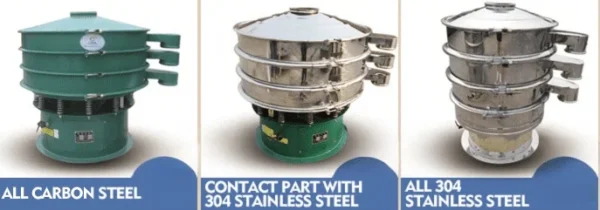

Equipment details:

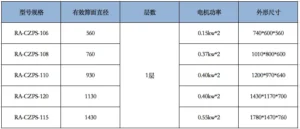

Equipment parameter

Message

Contact us

Welcome to our factory. We will provide you with the most professional mining machinery solutions

You may contact me through the following methods to obtain all information regarding the machine.

Huang [Sales Manager]

E-mail:info@vibratingscreenq.com

Mobile/WhatsApp/WeChat: +86 17337365719

Henan Quanshun Vibration Equipment Co., Ltd.

Address: Jinghua Road, Xiaojizhen Town, Xinxiang County, Xinxiang City, Henan Province, China

If you place an order, we will arrange delivery within 5 business days after receiving your payment!