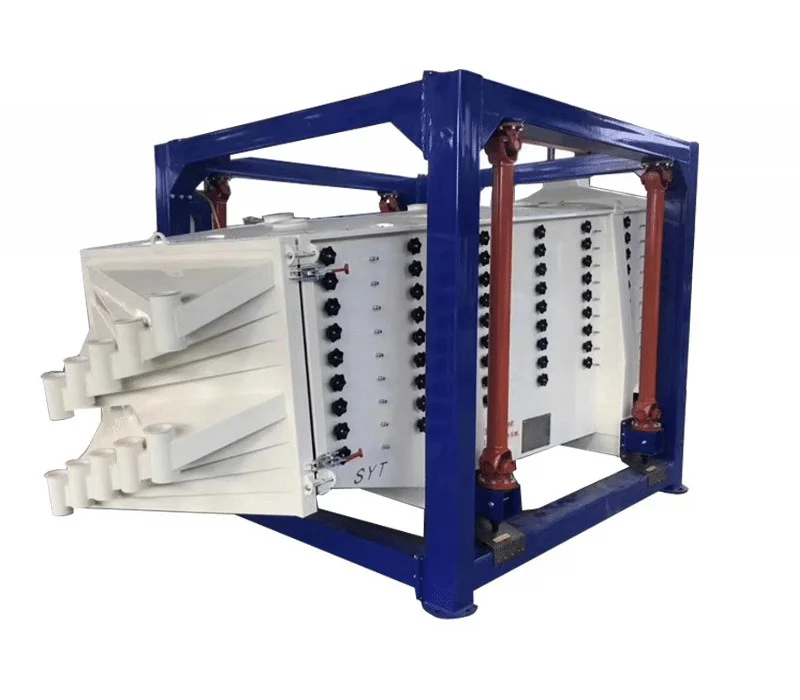

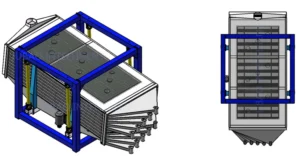

Square swing screen

Application range:

suitable for chemical, metallurgy, non-ferrous metals, non-ferrous metals, food, abrasives and other industries

Chemical (fertilizer, resin, melamine, soda ash, etc.) food (starch, salt, sugar, milk powder, etc.) metallurgy, non-ferrous metals, non-ferrous metals, magnetic materials, etc.

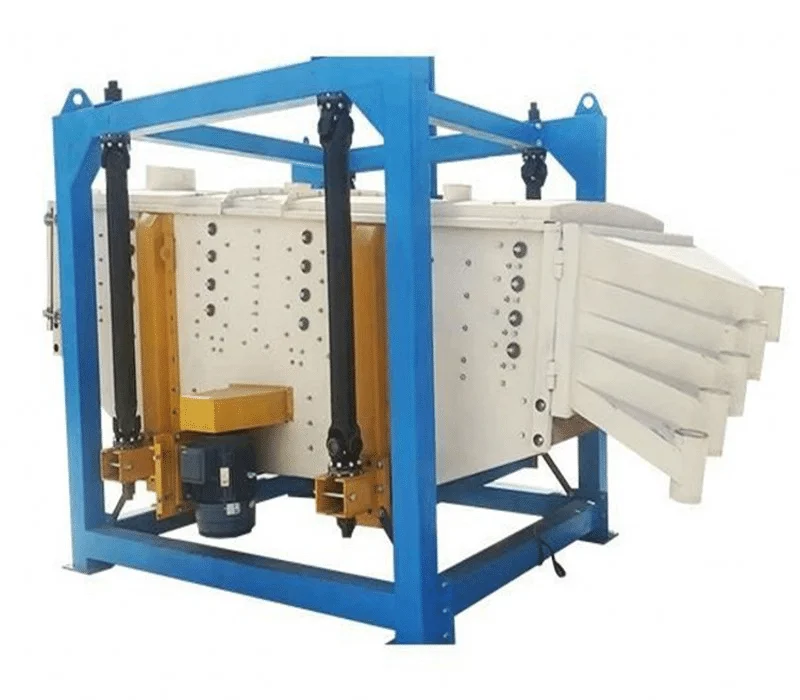

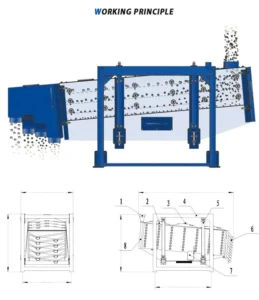

Working Principle

After the swing screen is started, the equipment shaking body, that is, the screen box,

reciprocates back and forth under the action of inertial force, and the screen box and

the screen surface are conjoined to shake periodically, so that the materials on the

screen surface will move in a directional jumping motion together with the screen box. .

The square rocking screen can also be called a reciprocating vibrating screen. The

vibration force generated by the motor drive device is an inertial force that changes in

a certain direction around a fixed axis. The essence is the reciprocating inertia formed

by the rotation of the eccentric wheel around the fixed axis. force. According to the

structural characteristics and working principle of the R series square rocking screen,

the screen surface is generally arranged horizontally or slightly inclined (the inclination

angle is 0°~5°). The working principle of the R series square rocking screen is: after the

rocking screen is started, the equipment rocking body, that is, the screen box,

reciprocates back and forth under the action of inertial force, and the screen box and

the screen surface are connected periodically to shake, so as to make the screen

surface The material moves in a directional jumping motion with the screen box.

During the period, the material smaller than the sieve hole falls to the lower layer

through the sieve hole and becomes the under-sieve material, and the material larger

than the sieve hole diameter is discharged from the discharge port after continuous

tumbling and jumping motion, thus completing the screening work. It can be seen

from the working principle of the R series square rocking screen that the eccentric

wheel distance of the transmission mechanism has an important influence on the

movement trajectory of the material and the residence time of the material on the

screen surface, that is, it has an opposite effect on the processing capacity of the

screen and the screening efficiency influence. In actual screening operations, we can

make trade-offs in terms of production capacity and screening efficiency according to

specific circumstances.

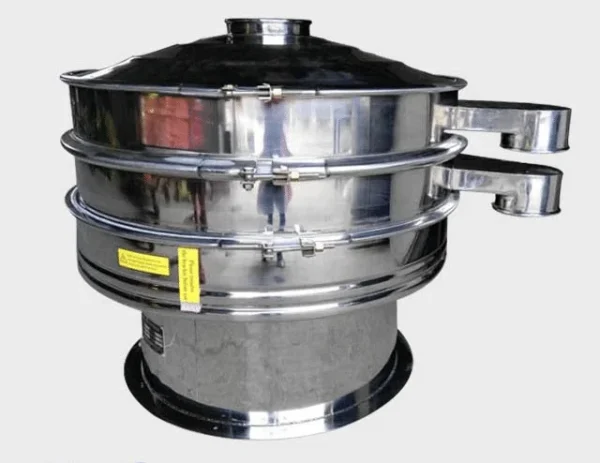

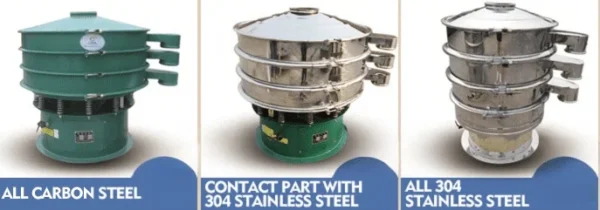

Features

- Using the principle of plane rotation, the distribution of materials on the screen is improved, and the utilization rate of the screen is effectively increased

- Suitable for cylindrical, flake and other irregular materials, the screening accuracy is as high as 98%, which is several times or higher than that of ordinary vibrating screens

- It can be used in single layer or multi-layer, and each layer of screen is equipped with a comb-type cleaning device

- Keeping clean throughout the work process can reduce environmental pollution

Equipment Parameter

| 型号

model |

有效筛分面积

Effective screening area(㎡) |

功率

power(KW) |

筛面倾角Screen surface inclination(°) | 层数

layer |

回转频次Rotation frequency(r/min) | 筛箱行程Screen box stroke(mm) |

| RA-CFYBS-1030 | 3 | 3 | 5~8 | 1~5 | 180~260 | 25~60 |

| RA-CFYBS-1036 | 3.6 | 4 | 5~8 | 1~5 | 180~260 | 25~60 |

| RA-CFYBS-1230 | 3.6 | |||||

| RA-CFYBS-1236 | 4.32 | 5.5 | 5~8 | 1~5 | 180~260 | 25~60 |

| RA-CFYBS-1530 | 4.5 | |||||

| RA-CFYBS-1536 | 5.4 | 7.5 | 5~8 | 1~5 | 180~260 | 25~60 |

| RA-CFYBS-1830 | 5.4 | |||||

| RA-CFYBS-1836 | 6.48 | 7.5 | 5~8 | 1~5 | 180~260 | 25~60 |

Message

Contact us

Welcome to our factory. We will provide you with the most professional mining machinery solutions

You may contact me through the following methods to obtain all information regarding the machine.

Huang [Sales Manager]

E-mail:info@vibratingscreenq.com

Mobile/WhatsApp/WeChat: +86 17337365719

Henan Quanshun Vibration Equipment Co., Ltd.

Address: Jinghua Road, Xiaojizhen Town, Xinxiang County, Xinxiang City, Henan Province, China

If you place an order, we will arrange delivery within 5 business days after receiving your payment!