Product

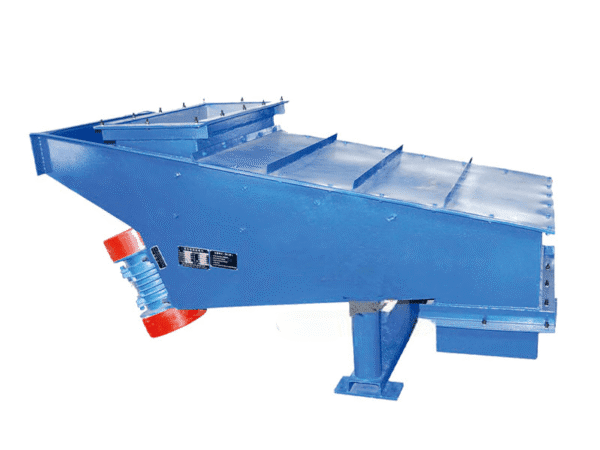

Motor Vibrating Feeder

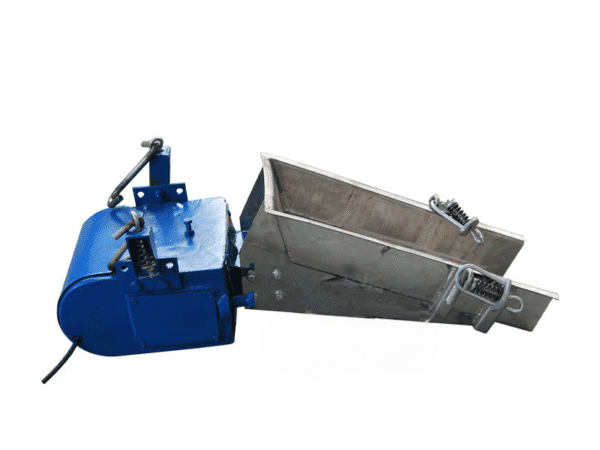

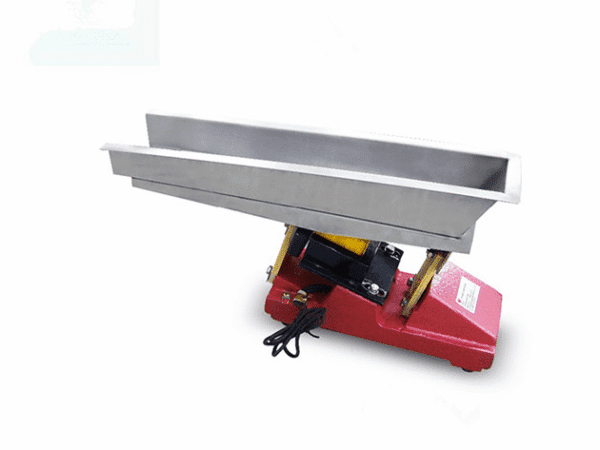

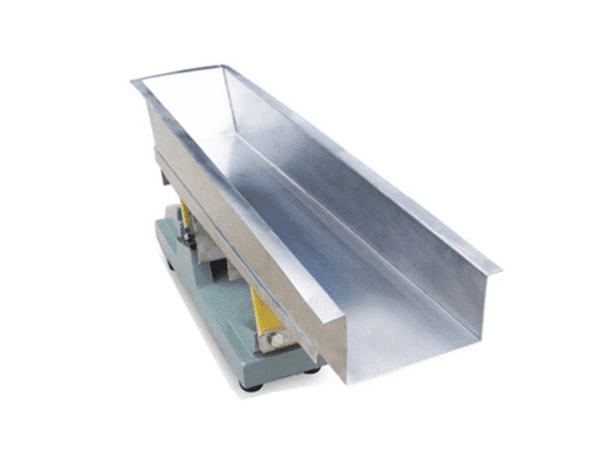

Electromagnetic Vibrating Feeder

Why choose electromagnetic vibrating feeder?

Application scope: Food industry, pharmaceutical industry, chemical industry, abrasive industry, non-metal industry, other industries, etc.

Application materials: Rock sugar, potato chips, cocoa beans, tablets, pharmaceutical powder, pharmaceutical granules, quartz sand, zirconium corundum, silicon carbide, plastic granules, rubber powder, PVC granules, etc.

Ton Bag Feeding Station

Vacuum Feeder

Why choose vacuum feeder

Low pollution: Reduce the pollution of the environment and personnel on materials and improve the cleanliness

Easy to operate: It takes up little space and can complete the small space of powder transportation, making the work space beautiful and generous, and is not limited by long or short distances

No leakage: The whole conveying process is carried out in a closed system without any powder leakage.

High efficiency: Reduce labor intensity and improve work efficiency

Applicable industry

Medicine, Food, Chemicals, Metallurgy, Building materials and other industries.

ELECTROMAGNETIC VIBRATION FEEDER

GZV electromagnetic vibrating Feeder is a kind of linear direction feeding equipment, which is widely used in mining, metallurgy, coal, building materials, chemical industry, electric power, grain and other industries. It can be used for the bulk, granular and powder material from the storage bin or other storage equipment uniformly, continuously or quantitatively to the receiving equipment.

SCREW CONVEYOR

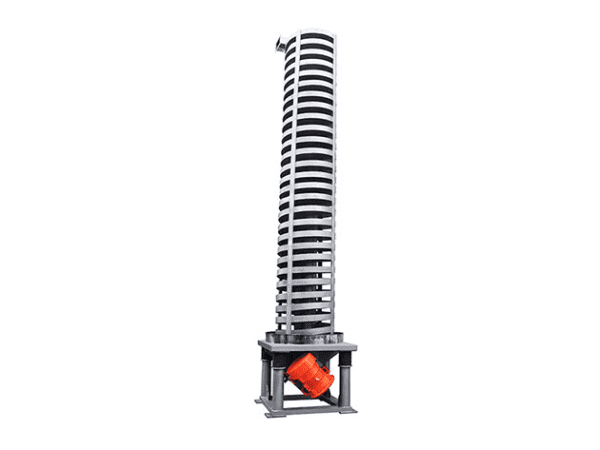

SPIRAL VIBRATION ELEVATOR

Vertical spiral elevator are used wherever bulk solids have to be conveyed in a vertical direction. These robust spiral elevators are suitable for conveying a host of bulk solids from various production processes. These can be fine to coarse-grained, as well as fragmentary bulk solids. Our spiral elevators are used in the chemical, pharmaceutical and food industries, and also in the raw material industry. The use of additional fixtures enables products to be treated by thermal (cooling/heating) or technical (drying) processes.

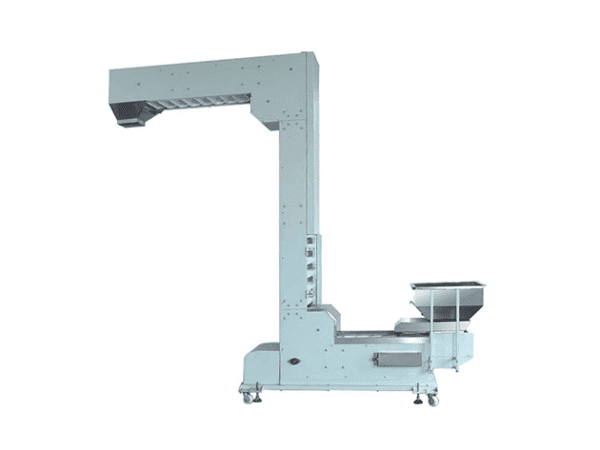

Z BUCKET ELEVATOR

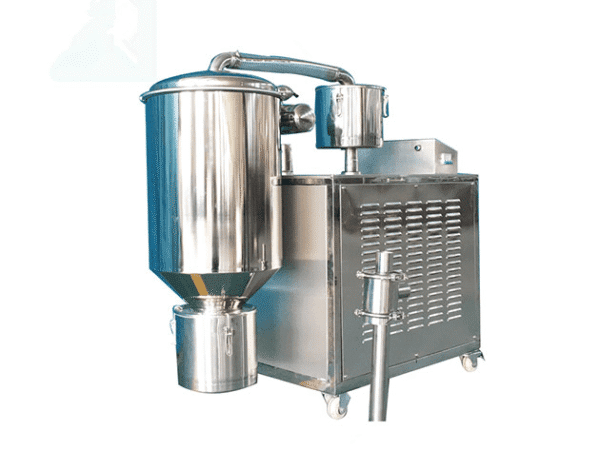

VACUUM CONVEYOR

Vacuum conveyors utilize a pressure differential to cause material to move from one end to the next. The vacuum feeder is the most advanced, perfect vacuum conveying equipment of powder material, granular material, powder-granular mixture. It can automatically transport a variety of material to mixing machine, packing machine, injection molding machine, grinder, etc...