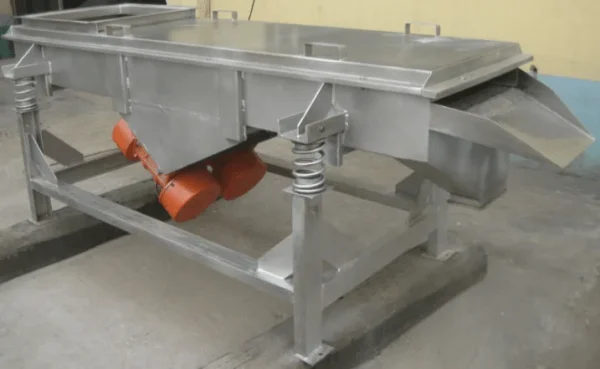

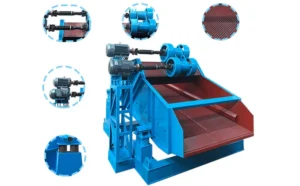

Mining linear screen

Scope of application:

metallurgy industry, mining industry, coal industry, building materials industry and chemical industry

Materials:

it is mainly used in the screening industry of bulk materials and small and medium-

sized granular materials such as metallurgy, mining, coal, building materials, electric

power and chemical industry, especially in the metallurgical industry. It is a commonly

used screening machine under the blast furnace trough, coking plant and concentrator.

Product categories

Recently Viewed Products

Working Principle

The mining linear screen adopts advanced technologies at home and abroad such as

vibration motor excitation, rubber spring vibration reduction, high wear-resistant

material screen plate, sealed screen box and advanced self synchronous vibration

principle. It has the characteristics of long service life, low noise and high screening

efficiency. It is a kind of vibration screening equipment suitable for sinter, natural ore,

coke and other powdery materials.

Mining linear screen is mainly used in metallurgy, mining, coal, building materials,

electric power, chemical industry and other industries, especially in metallurgy industry.

It is a common screening machine under blast furnace trough, coking plant and

concentrator

Product features

- Large processing capacity and high screening efficiency.

- The vibrator adopts bearing thin oil lubrication and external block eccentric structure. It has the characteristics of large exciting force, small bearing load, low temperature and low noise. (bearing temperature rise is less than 35 °).

- The overall disassembly and assembly of the vibrator is convenient for maintenanceand replacement, which greatly shortens the maintenance cycle. (it only takes 1 ~ 2 hours to replace the vibrator).

- The side plate of the screen machine adopts the whole plate cold work, no welding, high strength and long service life. The connection between the cross beam and the side plate adopts torsional shear high-strength bolts, without welding, and the cross beam is easy to replace.

- The screen machine adopts rubber spring to reduce vibration. Compared with metalspring, it has the advantages of low noise, long service life, stable passing through the commonvibration area, small dynamic load of each fulcrum of the screen machine and so on.

- Flexible coupling is adopted for the connection between motor and vibration exciter,which has the advantages of long service life and small impact on motor.Mining linear screen is mainly used in metallurgy, mining, coal, building materials, electric power, chemical industry and other industries, especially in metallurgy industry. It is a common screening machine under blast furnace trough, coking plant and concentrator.

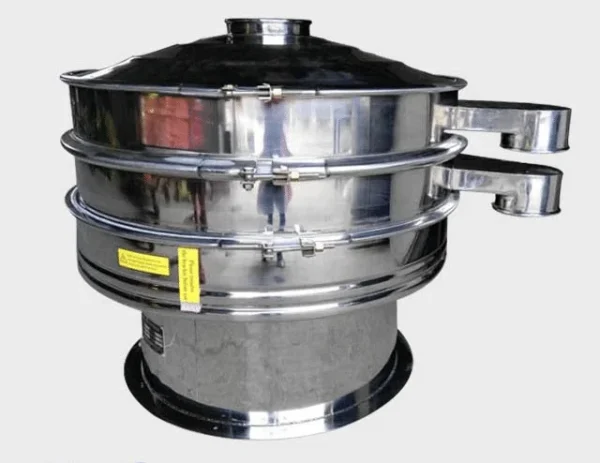

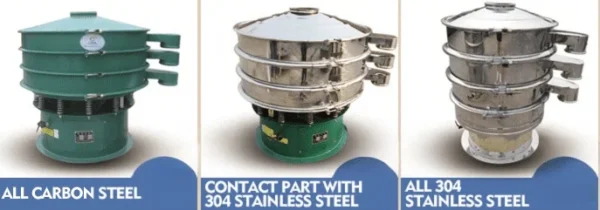

Equipment details

Equipment Details

| 型号

model |

外筛直径

Outer screen diameter(mm) |

处理量

Processing capacity(t/h) |

振次

Vibration times(min) |

双振幅

Double amplitude(mm) |

功率

power(kw) |

| RA-KJS-1230 | φ1200 | 10-18 | 960 | 1-5 | 2*2.2 |

| RA-KJS-1530 | φ1500 | 18-25 | 960 | 1-5 | 2*3.0 |

| RA-KJS-1830 | φ1800 | 25-35 | 960 | 1-5 | 2*5.5 |

| RA-KJS-2030 | φ2000 | 35-50 | 960 | 1-5 | 2*7.5 |

Case

You may contact me through the following methods to obtain all information regarding the machine.

Huang [Sales Manager]

E-mail:info@vibratingscreenq.com

Mobile/WhatsApp/WeChat: +86 17337365719

Henan Quanshun Vibration Equipment Co., Ltd.

Address: Jinghua Road, Xiaojizhen Town, Xinxiang County, Xinxiang City, Henan Province, China

If you place an order, we will arrange delivery within 5 business days after receiving your payment!

Message

Contact us

Welcome to our factory. We will provide you with the most professional mining machinery solutions

You may contact me through the following methods to obtain all information regarding the machine.

Huang [Sales Manager]

E-mail:info@vibratingscreenq.com

Mobile/WhatsApp/WeChat: +86 17337365719

Henan Quanshun Vibration Equipment Co., Ltd.

Address: Jinghua Road, Xiaojizhen Town, Xinxiang County, Xinxiang City, Henan Province, China

If you place an order, we will arrange delivery within 5 business days after receiving your payment!